R3 Reuse Program

The R3 Service Program incorporates a Reuse, Reduce, Recycle for Sustainability philosophy. The program is designed as a multi-tiered shipping solution for Pharma, Diagnostics, Animal Health, Food and Cannabis companies that ship pallets of product across the globe AND need the assurance of a temperature-monitored environment. Cryopak provides a Green solution which is designed to minimize waste and reduce the carbon footprint while providing an economical shipping solution.

Package Testing

When you need to get a package validation testing project done quickly to meet a tight deadline, you want to know your testing laboratory has the capacity to turn things around accurately and on-time.

The DDL testing facility located in Edison, NJ has the capacity and expertise to get your package validation testing projects turned around fast, accurately and on time to meet your tight deadline. The DDL lab in Edison offers a full suite of package testing for the pharmaceutical, medical device, and consumer goods industries.

Temperature Mapping

Key Element in Risk Management. Temperature mapping is performed to generate a temperature profile of the facility, in order to ensure it maintains the temperature range required by the specific temperature sensitive products. It helps protect their value by identifying potential environmental control problems before products become ineffective or spoiled.

It’s also an essential exercise to determine the location of the real-time monitoring system sensors.

- Required by the FDA and Health Canada

- Solutions for every budget

- Access to experts with years of experience

Thermal Equipment Qualification

Pass Quality Audits with Peace of Mind. Thermal equipment qualification is performed to ensure the equipment is properly installed according to the manufacturer specifications and your internal procedures. The protocol is written to allow technical analysis of all applicable installation requirements and operational functions of your fridge, cold room or freezer.

It’s also an essential exercise to determine the location of the real-time monitoring system sensors.

- Scientific evidence-based approach

- Clearly documented report

- Access to experts with years of experience

Shipping Lane Mapping

Understand your own Shipping Routes. Shipping lane mapping is performed to create ambient profiles that realistically reflect those found in a given distribution system. This will provide you on-going environmental data about factors that influence your cold chain system, allowing you to be in control of your unique shipping routes.

It’s an essential element in successful packaging design and selecting distribution/logistics partners for temperature sensitive products.

- Scientific evidence-based approach

- Based on your specific needs

- Access to experts with years of experience

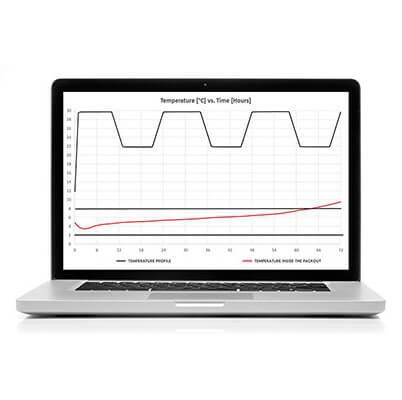

CFD Modeling & Thermal Simulation

Streamline packaging design. CFD Modeling, or thermal modeling, is an engineering simulation that analyzes fluid flow and/or heat transfer in a virtual environment. It identifies physical forces and flow characteristics that are sometimes impossible to measure or gain insight into otherwise.

It also allows you to do a comparative analysis between different packaging configurations or temperature profiles in order to choose the best option for your requirements, within a short timeline. It’s an essential element in successful packaging design.

Our team uses Ansys Fluent, the most powerful computational fluid dynamics (CFD) software tool available. This software is used by research centers, universities, and in virtually all industries worldwide.

- Cost effective: No prototype or inventory required

- Fast: Testing can be done in a matter of days

- Optimized packout: Test multiple configurations and choose the best option